Battery | Article – 28.05.2025

POWER ELECTRONICS: A STRATEGIC ASSET

FOR ELECTRIC VEHICLES

In a changing world, innovation in the automotive sector is not limited to electric motors. Behind every high-performance electric vehicle lies an essential, but often overlooked technology: power electronics. At Ampere, we see it as a strategic lever to not only optimize vehicle performance but also reduce costs. What is power electronics, why does this technology influence electric mobility and how does Ampere, together with its partners, drive innovation in this key sector? Decryption.

Power electronics, a key element of electric vehicles

When we talk about electric car, we inevitably refer to the electronics that is essential to manage the main functions of the vehicle such as: acceleration, braking, driving aids (ADAS) or the management of thermal and electrical energy.

Essential in this energy management, power electronics influences the charging and autonomy of an electric car as well as its performance by limiting losses during the transfer of energy between the battery and the component that consumes it.

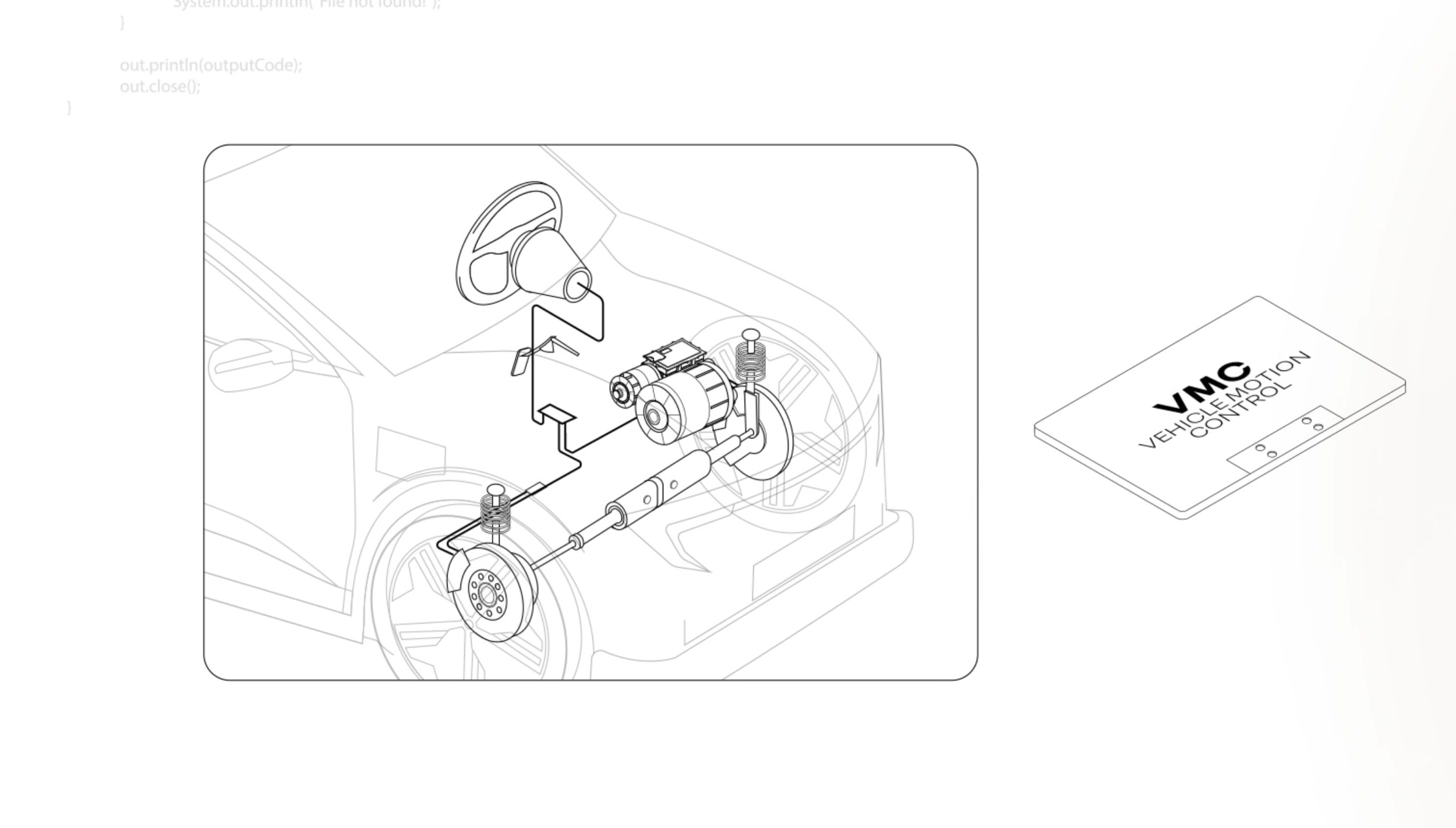

In an electric vehicle, each component—battery, engine, and other on-board systems requires a specific voltage and current. To ensure optimal operation, power electronics modules play a fundamental role in converting and regulating electrical energy.

Specifically, the modules perform several essential functions:

- The on-board charger converts alternating current (AC) from a terminal or household socket into Direct Current (DC) power compatible with the vehicle battery. It also allows, thanks to the V2G (Vehicle to Grid) function on our latest vehicles, to offer a new service to the customer by allowing the car to serve as a backup to the electricity network and thus contribute to the overall reduction of CO2.

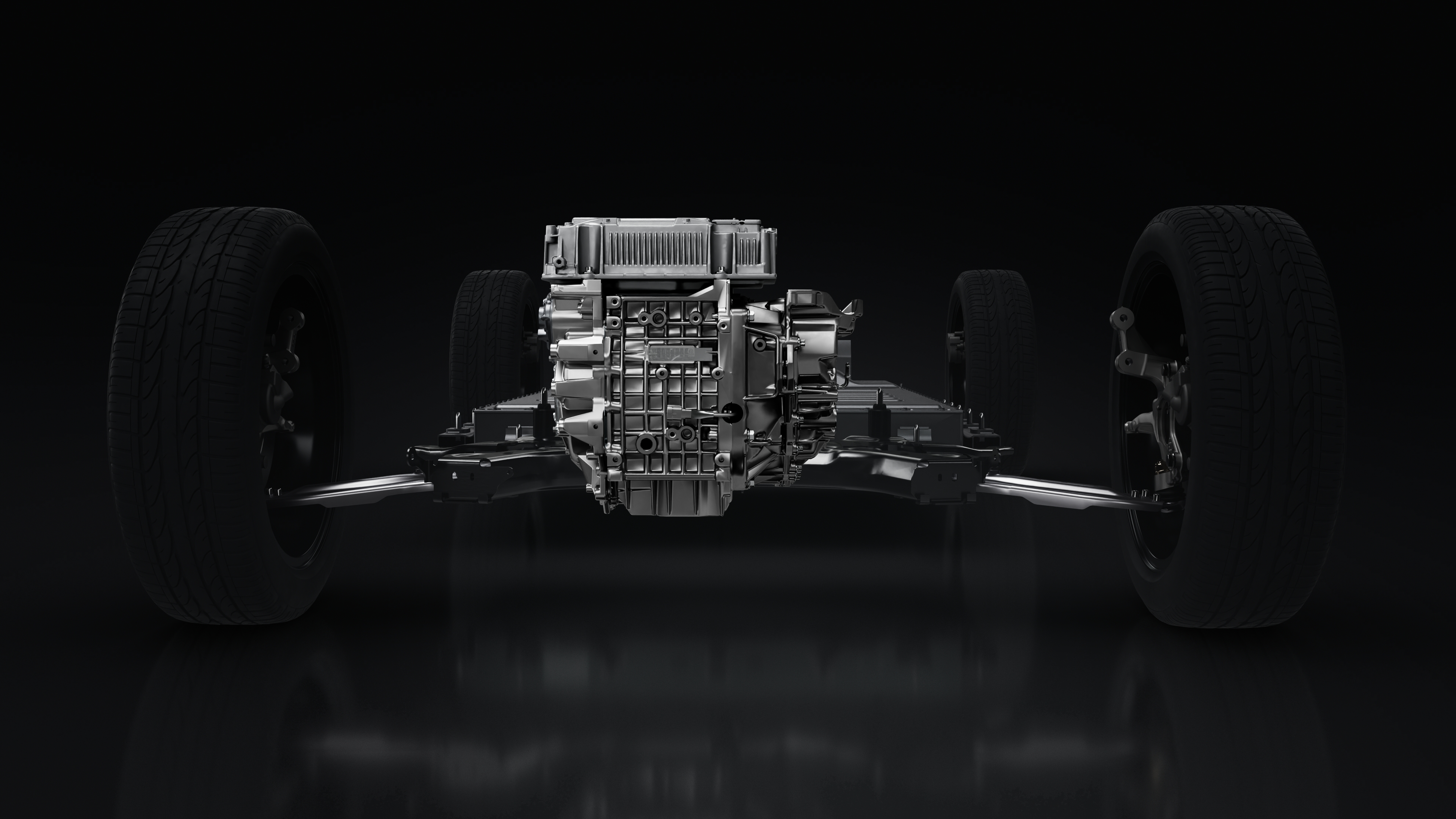

- The inverter converts the energy stored in the battery into alternating current to power the engine.

- The DC-DC converter converts high voltage current from the battery (usually around 400V) to a lower voltage, often 12V or 48V, for auxiliary equipment (headlights, air conditioning, radio, etc.).

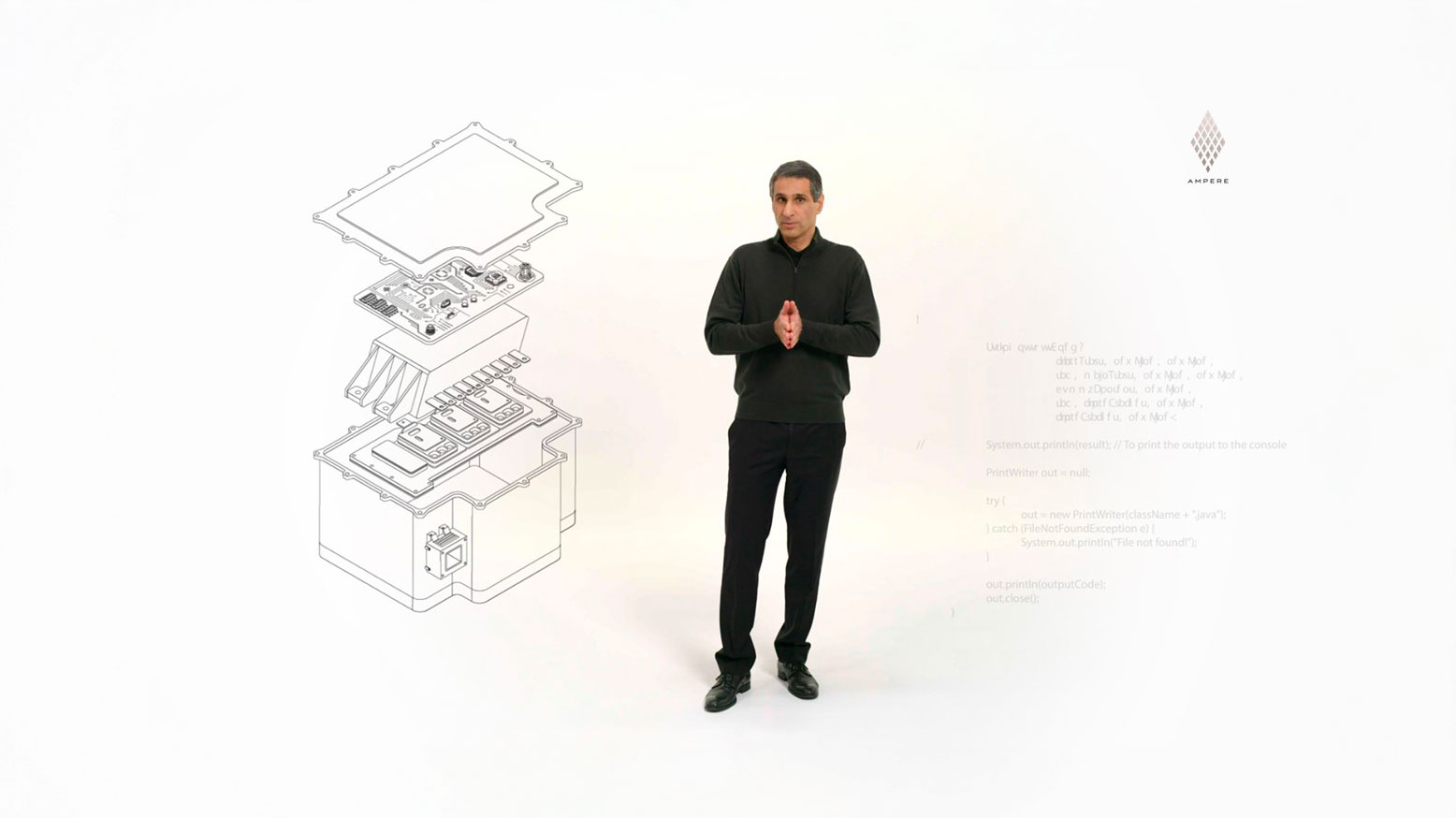

Mehdi Gati, Power and Battery Electronics Project Manager, explains how this technology is essential to manage the autonomy, ease of recharging and performance of electric vehicles

Optimize costs and secure electronic components supply: a global strategy of partnerships

Power electronics account for a significant share of the overall powertrain cost of electric vehicles, but it is also one of the key factors in performance. Ampere relies on an innovative and more compact architecture by combining, for example, the DC-DC converter and the on-board charger. Grouping different electronic components allows to pool functions, reduce the number of parts and thus the overall cost. This also saves space and weight, increasing vehicle autonomy and freeing up space for passengers.

But to ensure a sustainable reduction in costs, it is not enough just to optimize the design of electronic systems: you also have to secure their supply. In a context marked by geopolitical tensions and dependence on a limited number of suppliers, controlling the value chain has become an essential strategic issue. That’s why Ampere has established key partnerships.

- E2CAD, an expert in electronic board design and low-level software, works closely with the Ampere teams.

- STMicroelectronics will provide high-performance SiC (silicon carbide) semiconductors that will enable increased energy efficiency. Silicon carbide components have much lower electrical losses, which reduces energy consumption and improves the autonomy of electric vehicles. STMicroelectronics and Ampere have collaborated on a power system that will power the new generation of Ampere’s electric motors. Designed to have an optimal performance/size ratio, the power system will be deployed on the entire range of electric vehicles from Ampere. It will equip 400-volt battery vehicles and 800-volt electric segment C vehicles, allowing for greater range and faster charging. The 800 volt architecture is one of the keys to charging the battery from 10% to 80% in 15 minutes or less.

Through these collaborations, Ampere ensures reliable availability of critical components. This integrated approach not only reduces costs but also strengthens industry’s resilience to market fluctuations.

Recycling, environmental impact, intrinsic energy: the other levers of innovation

If cost, efficiency and energy density have become essential criteria, taken into account by all market players and widely expected by customers, reducing the environmental impact is now becoming an essential lever for more responsible and sustainable design.

Sustainable design is essential: integrating recyclability criteria and optimized management of electronic waste from the design stage helps to limit ecological impact. The semiconductor manufacturing, which is very water and energy intensive, nevertheless sees its investment quickly compensated thanks to their efficiency. At Ampere, we adopt a sustainable circular economy approach by integrating recyclability and energy efficiency constraints from the design stage, thus anticipating environmental and regulatory challenges.

Power electronics is an innovation driver for electric vehicles. Thanks to compact architectures and advanced component integration, Ampere improves the energy efficiency of its electric vehicles while reducing costs. By mastering the entire value chain and developing ever more efficient systems, power electronics is becoming a key factor for Ampere to accelerate the adoption of electric mobility in Europe and beyond.

Read also